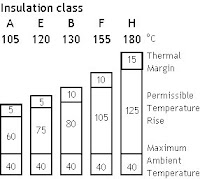

There

are insulation papers kept between phases of the winding and in the slots to

keep insulation between windings and lamination core. Those insulation papers

are designated with a class which determines the maximum temperature those

insulation papers can withstand without an effect to the motor life time. Following image shows specifications of each insulation class

So

it is very important to keep the hot-spot temperature (Point where the temperature

is highest) below the maximum permissible temperature for relevant insulation

class used in that particular machine.

A common rule of

thumb is that the life of the motor insulation will be halved every tie motor

is operated above 10°C of rated insulation temperature. This diagram shows how

motor winding life time depends on excess temperature rise which motor is operated.

No comments:

Post a Comment